Refrigerated Air Dryer

👉Energy Efficiency

👉Reliable Performance

WHY HANVI COMPRESSORS PVT LTD.

.png)

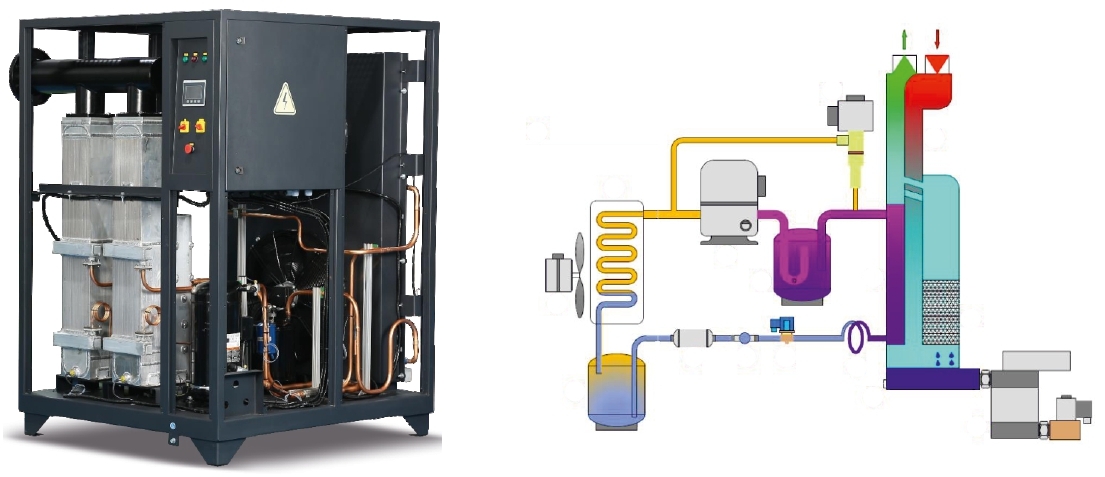

Refrigerated Air Dryer

Moisture Removal: Refrigerated Air Dryers effectively extract moisture from compressed air, preventing corrosion, contamination, and malfunctions in pneumatic equipment.

Improved Product Quality: By eliminating moisture, these dryers enhance product quality in industries like food and beverage, pharmaceuticals, and electronics manufacturing, where moisture can compromise integrity.

Energy Efficiency: Modern Refrigerated Air Dryers incorporate advanced technology to minimize energy consumption, contributing to cost savings and environmental sustainability.

Consistent Air Pressure: Maintaining consistent air pressure is vital for equipment efficiency and reliability. Refrigerated dryers help stabilize air pressure by removing moisture that can cause fluctuations.

Extended Equipment Lifespan: Moisture can accelerate wear and tear on pneumatic tools and machinery. By keeping compressed air dry, these dryers extend the lifespan of equipment, reducing maintenance and replacement costs.

Compliance with Industry Standards: Many industries have stringent requirements for air quality. Refrigerated Air Dryers ensure compliance with these standards, safeguarding product integrity and regulatory compliance.

| MODEL | FLOW | MAX INLET PRESSURE | NOMINAL CONNECTED POWER | INLET/OUTLET SIZE | ||||||

| cfm | M3/MIN | Bar g | KW | Bar | ||||||

| HAD 020 | 20 | 0.57 | 16 | 0.16 | 1/2” BSP-F | |||||

| HAD 030 | 30 | 0.85 | 16 | 0.16 | 1/2” BSP-F | |||||

| HAD 040 | 40 | 1.15 | 16 | 0.21 | 1/2” BSP-F | |||||

| HAD 050 | 50 | 1.42 | 16 | 0.29 | 1/2” BSP-F | |||||

| HAD 080 | 80 | 2.27 | 14 | 0.39 | 1” BSP-F | |||||

| HAD 0100 | 100 | 2.83 | 14 | 0.48 | 1.1/4” BSP-F | |||||

| HAD 150 | 150 | 4.25 | 14 | 0.71 | 1.1/4” BSP-F | |||||

| HAD 200 | 200 | 5.66 | 14 | 0.82 | 1.1/4” BSP-F | |||||

| HAD 300 | 300 | 8.49 | 14 | 0.92 | 2” BSP-F | |||||

| HAD 400 | 400 | 11.33 | 14 | 1.4 | 2” BSP-F | |||||

| HAD 500 | 500 | 14.16 | 14 | 1.5 | 2.1/2” BSP-F | |||||

| HAD 600 | 600 | 17 | 14 | 2.1 | DN80-PN16 | |||||

| HAD 900 | 900 | 25.48 | 14 | 2.85 | DN80-PN16 | |||||

| HAD 1000 | 1000 | 28.33 | 14 | 3.1 | DN80-PN16 | |||||

| HAD 1245 | 1250 | 35.51 | 14 | 3.5 | DN80-PN16 | |||||

Download Form

Copyright © All rights reserved by Hanvi Compressors Pvt Ltd.